Following recent turmoil in the global employment market, countless businesses have reported problems in find the quantity and quality of workers needed to keep operations running smoothly. This labor shortage is being felt particularly strongly across the warehousing, logistics and e-commerce sectors, which are having to handle more packages than ever with fewer workers. Fortunately, both challenges can be partly addressed by a single piece of technology – the Prime Vision Flow Projector.

Examining the logistics labor shortage

Almost three-quarters of warehouse operators in the U.S. say they can’t find enough staff[1]. On top of that, even when they can find new employees, it’s often hard to retain them. For instance, Amazon struggles to keep warehouse workers for long periods, reporting that only one in three of their employees remain for more than 90 days after being hired[2].

There’s no single reason for this. Rather, there is a broad combination of factors that make the job both physically and mentally demanding. High turnover rates are driven by the repetitive and sometimes strenuous nature of manual sorting tasks, which can lead to job dissatisfaction and burnout.

This leaves warehouse operators with two key challenges. Firstly, they need to find a way to reduce turnover by improving worker satisfaction by alleviating the monotony and strain of manual sorting tasks. Secondly, they need to find a way to address the issues they are facing right now and find a solution that can help workers operate effectively with minimal training and experience. These are two areas where Prime Vision’s Flow Projector can help.

[1] Survey: 73% of warehouse operators can’t find enough labor – Freight Waves

[2] Fewer People, More Demand: Labour Shortages Are Set to Define Logistics in 2023 – The Business Concept

The Prime Vision Flow Projector

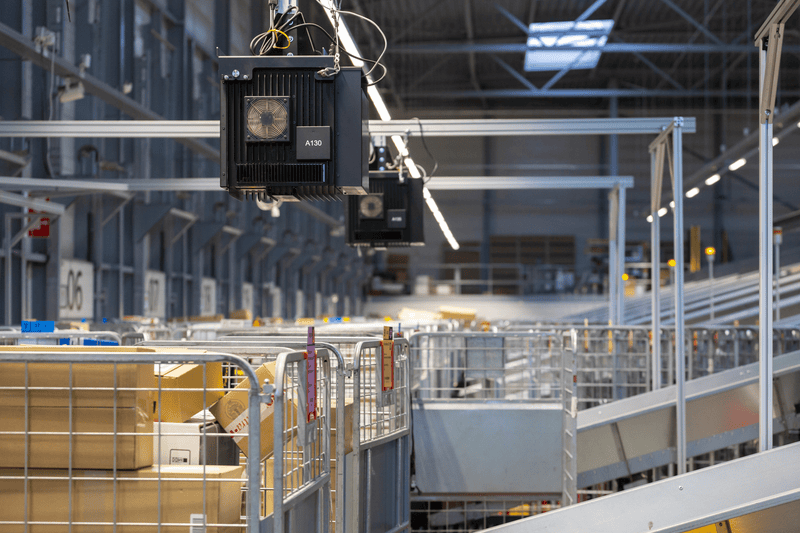

The Prime Vision Flow Projector is an advanced technological solution designed to optimize the efficiency and accuracy of parcel sorting processes in warehouses and e-commerce fulfilment centers. Essentially, it is a compact unit that houses a combination of recognition sensors, laser projection technology, and vision recognition software. When installed above a sorting area, the Flow Projector can immediately identify the destination of a parcel by reading its barcode. Using a laser beam, it projects the sorting destination directly onto the parcel, providing clear and precise guidance for the sorting personnel.

As parcels move along the conveyor, the system tracks their movement, maintaining the projected sorting number on each parcel until it is collected. This continuous tracking ensures that workers can easily and accurately sort parcels without the need for handheld scanners or other additional tools, significantly streamlining the process.

Moreover, the display be configured to not only show the final sorting destination, but also the sequence in which packages should be loaded into trucks. This feature is particularly beneficial for optimizing loading efficiency and ensuring that parcels are loaded in the correct order for delivery routes.

The technology’s plug-and-play capability means that it can be easily integrated into most existing sortation systems without requiring extensive modifications or large investment costs.

The benefits

More efficient sorting

The Prime Vision Flow Projector significantly boosts productivity, with users usually experiencing at least a 50% increase. This improvement stems from the ability to project information onto multiple parcels simultaneously, allowing operators to handle several items at once. This capability drastically reduces the time spent on repetitive tasks, such as scanning each parcel individually with a handheld device.

By enabling workers to sort multiple parcels in a single action, the Flow Projector optimizes the workflow and increases the throughput of the sorting process, leading to more efficient overall operations.

Improved job satisfaction

The Flow Projector eliminates the need for handheld scanners or other cumbersome technology, freeing workers from repetitive and physically demanding tasks. This means employees spend less time manually sorting parcels and always have both hands free, making it much easier to pick up and manipulate the items.

By reducing the physical strain and monotony associated with traditional sorting methods, the Flow Projector enhances job satisfaction. Workers appreciate the intuitive nature of the technology, which simplifies their tasks and reduces stress. As a result, they are more likely to find their work engaging and fulfilling, leading to higher morale and lower turnover rates.

Limited or no training required

One of the standout benefits of the Flow Projector is its ability to quickly onboard staff, including those who may not speak the local language. Traditional training methods can take up to three days, but this is reduced to about half an hour with the Flow Projector.

Indeed, the technology is so intuitive that workers often require no formal training at all – they can simply observe the system in operation and immediately understand how to use it. This makes the Flow Projector an excellent tool for environments with high turnover or when employing temporary staff.

Fast and easy deployment with quick ROI

The Flow Projector is designed to be affordable to install and does not require a redesign of the existing warehouse infrastructure. Installation is quick, typically completed within a day, making it accessible for businesses of various sizes. Unlike other solutions that may take weeks or months to implement, the Flow Projector can start delivering real, tangible benefits within an hour of coming online. Its plug-and-play nature ensures minimal disruption during deployment.

Additionally, its scalability allows for gradual implementation across multiple warehouse exits, enabling businesses to expand its use as needed without significant upfront costs. This quick return on investment (ROI) makes the Flow Projector a highly attractive option for improving efficiency and productivity in warehouse operations.

Optimized Sequencing

Another great benefit of the Flow Projector is its ability to optimize sequencing. By ensuring that parcels destined for early delivery are loaded first, it enhances delivery efficiency and streamlines the process. This smart sequencing reduces fuel consumption and lowers CO2 emissions, making it a win for both logistics operations and the environment.

The future of sorting

The Prime Vision Flow Projector is a key solution for warehousing and e-commerce businesses grappling with labor shortages. By integrating advanced recognition sensors, laser projection technology, and vision recognition software, it addresses the dual challenges of reducing worker turnover and enhancing operational efficiency.

This allows it to not only solve immediate operational challenges but also position warehouses for long-term success by fostering a more efficient, satisfied, and stable workforce. As Prime Vision continues to innovate and support the warehousing sector through technological innovations, businesses can look forward to even greater enhancements in productivity and efficiency.