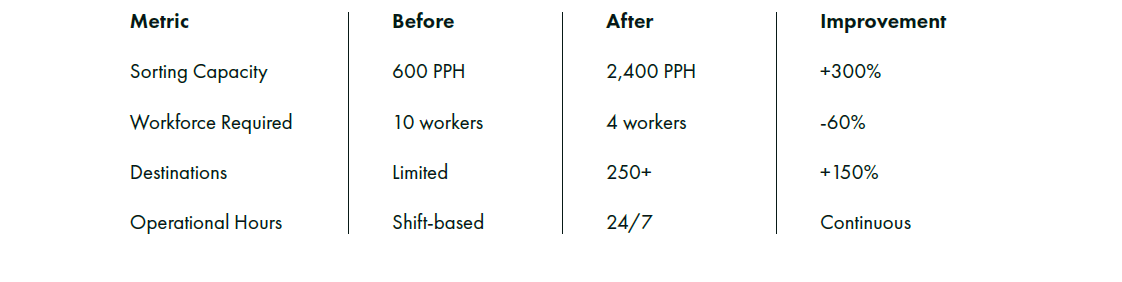

At glance

- Industry: Logistics & Supply Chain

- Challenge: Manual sorting limited to 600 parcels/hour

- Solution: 80-robot automated sorting system

- Results: 2,400 parcels/hour with 60% workforce reduction

Our client, a leading international logistics company, struggled to improve sorting speed and accuracy while handling increasing parcel volumes. Their manual sorting process, with 10 workers, could only manage 600 parcels per hour, leading to inefficiencies and peak-time bottlenecks. Today, with our robotic sorting solution, just four workers oversee 80 robots, efficiently sorting more than 2,400 parcels per hour to 250 destinations.

Challenge: Boosting sorting throughput and efficiency

The client sought a way to enhance operational efficiency without requiring large-scale fixed infrastructure investments. They needed a system that could:

- Process a high number of parcels per hour

- Sort to a large number of destinations: 250 or even more unique destinations

- Operate efficiently with just four infeeds

- Minimize labor dependency while ensuring 24/7 operational continuity

“Our manual process couldn’t keep pace with growing demand. We needed a solution that could scale quickly without massive infrastructure changes.” — Operations Director

Implementation Robotic Sorting at a scale

We introduced our Robotic Sorting Solution, tailored for the client’s operational needs. The system deployed 80 sorting robots, designed to efficiently navigate the warehouse floor, ensuring seamless, high-speed parcel distribution.

Deployment Process:

- Concept & Design: We created a detailed sorting layout optimizing robot pathways and infeed placement.

- Pilot Phase: A test setup at a central hub validated the system’s efficiency before full-scale deployment.

- Full Rollout: With proven results, the solution was implemented across multiple sites in just weeks.

Achieved results

The results have been transformative:

- Sorting Capacity: Increased from manual limitations to 2,400 parcels per hour

- Labor Optimization: four workers now oversees 80 robots instead of multiple employees manually sorting parcels

- Sorting Accuracy: The system consistently sorts to 250 destinations with near-perfect precision

- 24/7 Operation: Eliminates downtime due to breaks, illness, or shift changes

Benefits of the Autonomous Sorting solution

- Rapid Implementation: Deployment across multiple locations across the USA completed in weeks

- Scalability: Additional robots and new destinations can be added effortlessly

- Cost-Efficiency: Minimal upfront investment compared to traditional sorting machinery

- Reliability: Consistent performance with reduced dependency on fluctuating labor availability

Conclusion

As logistics companies face growing parcel volumes and labor shortages, robotic sorting provides a flexible, scalable, and cost-effective alternative to traditional sorting systems. With 2,400 PPH and 80 robots operating seamlessly, our client has now expanded this solution across multiple locations, reinforcing their commitment to operational excellence.